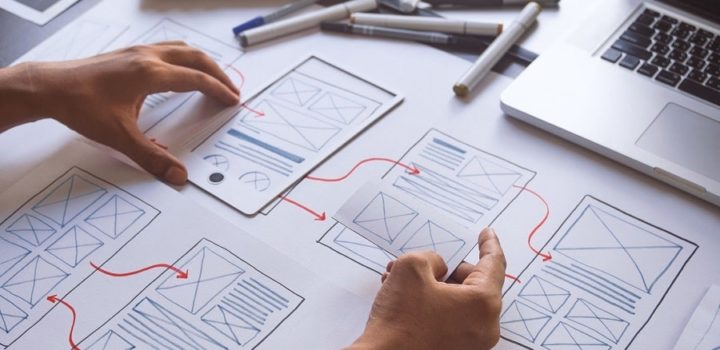

How to Build Your Prototype

Looking at a design on a screen, and wanting to see it in person, can be a difficult task sometimes. It can be daunting to imagine the prospect of undergoing the manufacturing process of building a prototype of your product. The money, the materials, and the risk that when you receive it, you realize the product needs drastic changes.

This small guide is here to help take you through the steps you need to remember when it comes to making your product a reality.

Finalize a Draft Design

Before you even start thinking about creating a physical product prototype, make sure you have made all the amendments you need to the draft design. You can always create multiple prototypes, but it is easier on the planet, and the wallet to do as much work before committing to creating the product. Also, if your product is a consumer product, maybe a survey with a small group before you commit to a physical prototype may help identify any critical flaws.

What Are You Testing?

This is another crucial question, what is the purpose of the physical prototype? Do you need to test the form, how it feels when the product is held in your hands? Are you testing functionality? Does it work best in a hot or cold condition, or is it tough enough to withstand the conditions that it is going to be used within? Before you commit to manufacturing the prototype, get these questions down first so as soon as you get it, you can hit the ground running and start refining what is needed before final production.

Choose the Right Supplier

This is the biggest factor that you need to take into account when looking to produce a prototype of your product. There are many companies out there that can produce your prototype, and also your final product. Companies such as TSMC exist with the right manufacturing procedures in place already, to get the production of your product off the ground. So, before you start thinking of what to test and what the product will look like, make sure you find the right supplier for your particular product.

Manage Your Costings

Next, costings. These are some of the greatest factors you need to take into account with any business decision. Building a prototype is no different. This is one of the main reasons to build a prototype as if you mass-produce a faulty product, this could lead to bad press, recalls and the dreaded ‘refund’. When it comes to building your prototype, make sure you keep the costs in mind. Transportation if the manufacturer is abroad. The costs of the materials and general production. All of these small numbers add up, and matter greatly!

What Is Next?

Go build it! A prototype of any kind of product is very exciting, you get to touch and feel your product for the first time. See how it looks in person rather than a device or paper. Get to see your product work, and see if it does the job you designed it for. Take the above points, and use them to go and build the best prototype, and enjoy the experience!